Overview of Forging Process

Forging is a metal working process by hammering or pressing hot metal into the metal dies. It is one of the oldest metalworking arts with its origin about thousands of years back.

Precision forging produce the final metal parts in a close to final shape or closetolerance forging way. When you need a product with near net shape or net shape, precision forging is the right choice to source, such forging process will refine the product to little or no machining. Comparing to the other metal forming processes, the precision forgings have advantages of higher mechanical properties, slight draft angles, close tolerances, small radii, and sound surface finish.

Forgings are often classified according to the temperature at which it is performed: cold forging, warm forging, and hot forging. For the latter two, the metal is heated, usually in a electric induction furnace. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.

Precision Forging is a forging process in which dies move towards each other and covers the work-piece in whole or in part. The heated raw material, which is approximately the shape or size of the final forged part, is placed in the bottom die. The shape of the forging is incorporated in the top or bottom die as a negative image. Coming from above, the impact of the top die on the raw material forms it into the required forged form.

Forging Workshop

The Advantages of Forging Process

1) High precision and therefore a high material utilization.

You will get a net or near-net-shape products after precision forging process, therefore no or very little machining process is required.

2) Better Mechanical Properties performance.

After the metal is forged, the metal flow line is even distributed along the contour shape, dense and continuous. For precision forgings, there is no leakage of metal fibre that caused by removing flash, which is very useful for improving stress corrosion resistance and fatigue resistance, hardness, yield strength and tensile strength of the the forging parts.

3) Available Complex Structure Forgings

The final forgings with complex structure and shape is totally available by precision forging process. When a metal parts is difficult to get by castings of other metal forming process, precision forging process is the right choice.

Available Materials for Forging Process

The most widely used materials for precision forging cover from steel, alloys steel and aluminium alloys.

- Alloy Steel (20Cr, 20CrMo, 20CrMnTi, 30CrMo, 35CrMo, 40Cr, 42CrMo...etc)

- Carbon Steel (1020, 1035, 1045, 1055, A105, Q235, Q345...etc)

- Stainless Steel (SS303, SS304, SS304L, SS316, SS316L...etc)

- Aluminum Alloys

Facilities for Steel Forging

Forging Tools Workshop

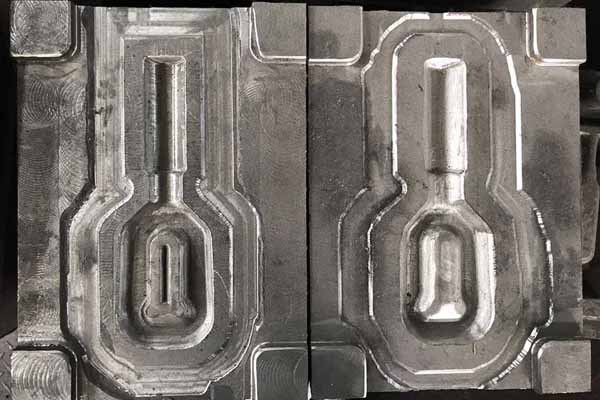

Forging Mould

Forging Toolings

Forging Workshop

Steel Forging Workshop

Heat Treatment Facilities

After Processing

Forgings after Machining

Applications of Precision Forgings

Due to the greater mechanical properties, easy to be machined and comparing lower porosity to the steel castings, forged parts are widely used in mechanisms and machines. And othersecondary processing such as heat treatment and surface treatment to achieve a finished part are very easy and convenient to be made for forgings.

As the precision forging supplier in China, RMC offer OEM custom forging parts and exporting service for customers from USA, UK, Australia, Canada, Russia, Italy, Spain, Germany, Sweden, Norway...etc. Such precision forgings are mainly involved in automotive components, agricultural machinery parts, oil & gas, railway freight car components, mining machinery parts and hydraulic systems. Some examples of shapes obtained by forging process: crane hook, engine connecting rod, spanner, gear blanks, crankshaft, camshaft, towing eye, flange, axles...etc.

Applications of Precision Forgings

Typical Products of Precision Forgings

Steel Forged Parts

Forging Steel Part

Connection Rod

Forged Crankshaft

Forged Bushing Bolt

Precision Forging Part

Alloy Steel Forging

OEM Forging Parts

Value Added Services:

We offer every possible secondary operations including heat treatment, machining, surface treatment, or metal fabricating. We provide all the value added services to make procuring steel forgings as easy and as cost effective as possible.

If you are interested in knowing more about metal parts made from steel forging, we can provide them for you.

русский

русский